Dear All, We would like to inform you that our office and factory will be closed for the Chinese New Year holidays from February 14 to 23, 2026. Normal operations will resume on February 24, 2026. Dur...

CARBONAL represents the latest technological advances in carbon-fiber bicycle rim & wheel performance products. Engineered from the trail up to be lighter, stronger, faster and more aerodynamic.

After more than 14 years of hard working on carbon rims & wheels, we finally learn what are important in this work, and we will never stop learning.

In the pursuit of ultimate performance, cyclists constantly seek ways to enhance their speed, agility, and efficiency on the road or trail. One area that has seen significant advancements is the development of carbon fiber bicycle rims & wheels, which have become synonymous with super-lightweight construction. Through the use of high-modulus carbon fiber, meticulous optimization processes, extensive testing, and valuable feedback from professional athletes, we have been able to create increasingly lighter carbon fiber rims without compromising strength or aerodynamics.

Our journey to ultra-lightweight carbon fiber rims & wheels begins with the selection of high-modulus carbon fiber, a material known for its exceptional stiffness and strength-to-weight ratio. This advanced material forms the foundation of our rims & wheels, providing the ideal platform for further refinement and optimization.

To ensure that our carbon fiber bicycle rims & wheels offer the perfect balance of weight and strength, we employ a rigorous and ongoing process of optimization. This involves meticulous layering and arrangement of the carbon fibers, as well as continuous experimentation with different designs and construction methods. Through this iterative process, we have been able to reduce the weight of our carbon rims & wheels while maintaining their structural integrity and durability.

But our commitment to lightweight construction goes beyond just material selection and design optimization. We also rely on extensive laboratory testing and real-world usage scenarios to gather valuable data and feedback on our carbon rims & wheels' performance. This comprehensive testing process allows us to identify any areas for improvement and make the necessary refinements to ensure that our carbon rims & wheels continue to push the boundaries of lightweight excellence.

Moreover, we are grateful for the invaluable insights provided by our partnered professional cyclists. Their firsthand experiences with our carbon rims & wheels on the racecourse offer a unique perspective on how our products perform under the most demanding conditions. Their feedback has been instrumental in guiding our development process, enabling us to create even lighter and more aerodynamic carbon rims & wheels that help riders like you go faster and perform better.

The result of our tireless efforts is a range of carbon fiber bicycle rims & wheels that offer an unbeatable combination of ultra-lightweight, high-strength, and superior aerodynamics. These carbon rims & wheels not only shave precious grams off your bike's overall weight but also contribute to a smoother and more efficient riding experience, allowing you to reach new speeds and achieve your goals on the road or trail.

As we continue to innovate and refine our carbon fiber rim & wheel technology, we remain committed to providing cyclists with the ultimate in lightweight performance. With our high-modulus carbon fiber, meticulous optimization process, and invaluable feedback from professional cyclists, we are confident that our carbon rims & wheels will continue to set the standard for lightweight, high-performance bicycle components for years to come.

RD & Production technology:

1. Accurate OD + ETRTO = perfect tubeless sealing + easy tire mounting.

2. Amazing flatness and roundness after molding, make sure our rim is born good.

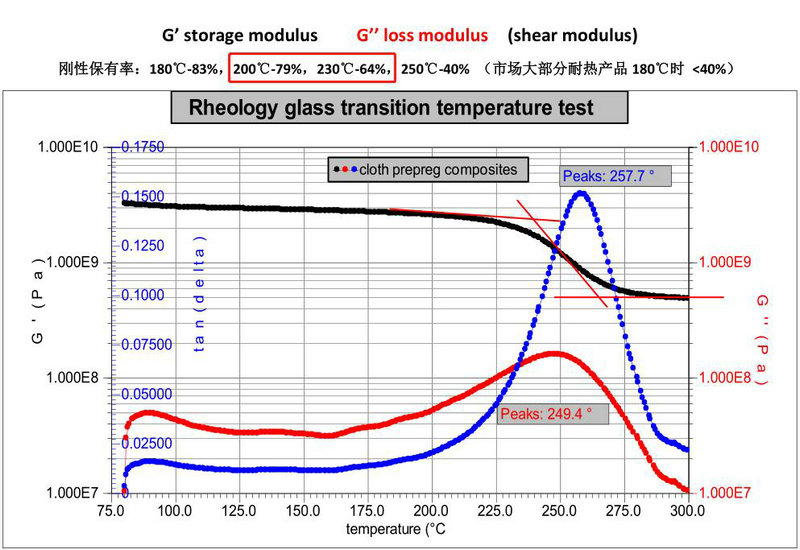

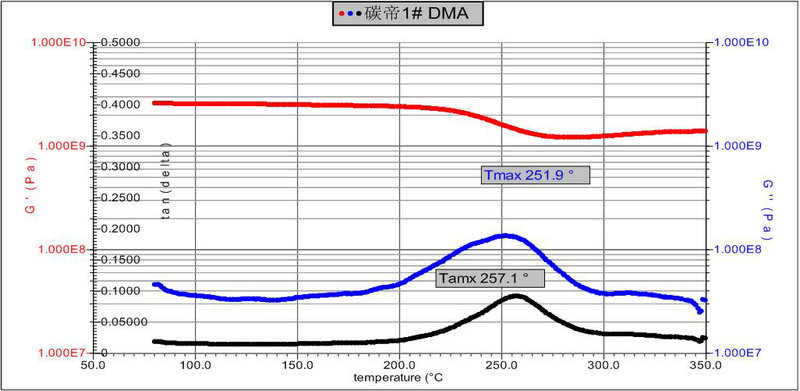

How: when heating reaches 200 degree, our resin remains 79% solidness. When heating up to 230 degree as what most of you can achieve when descending, our resin can still keep 64% solidness.

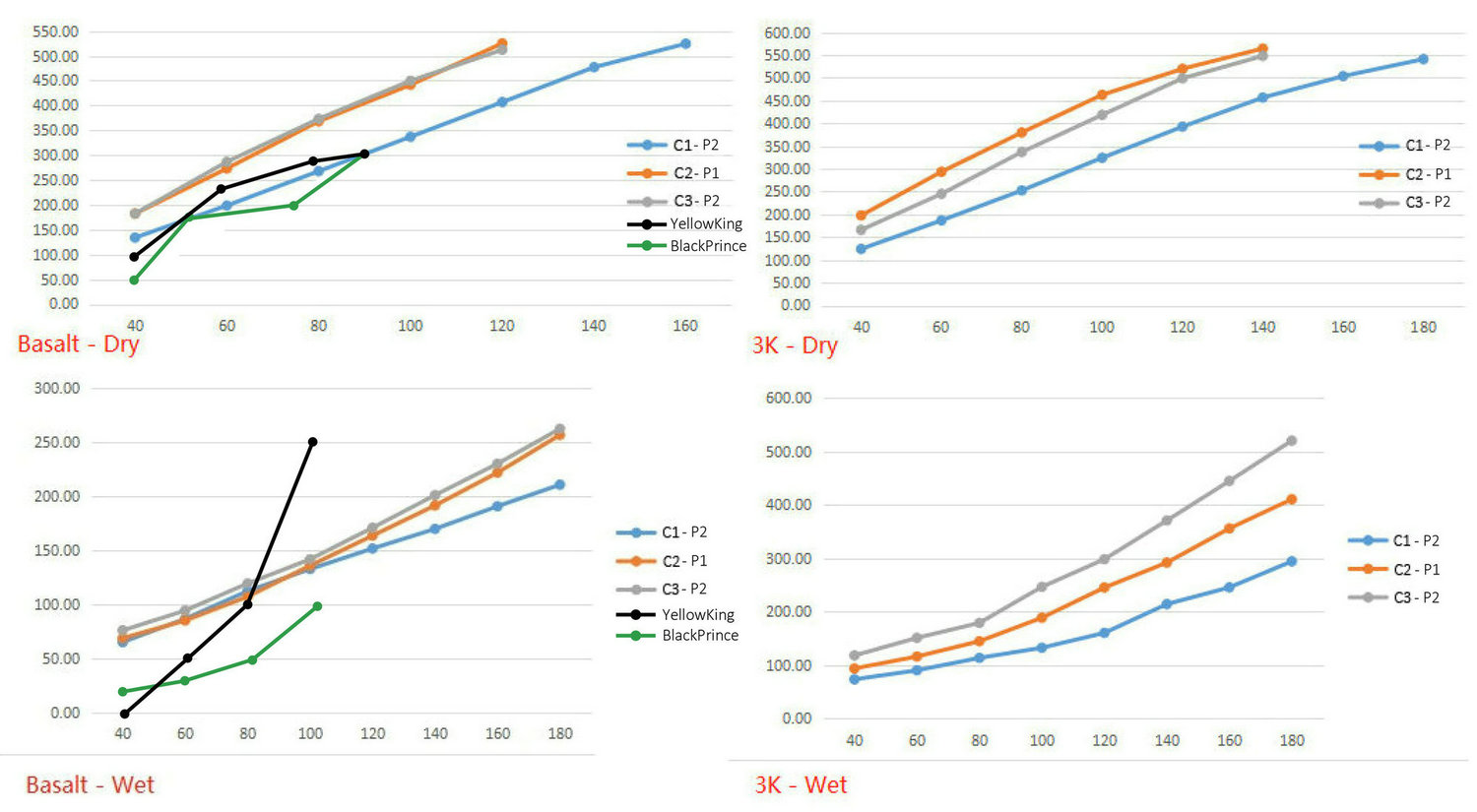

Since the rim doesn't have over heating issue, we suggest to use 3K twill brake track. When working with our special pad, you can get the best brake power both on dry and wet conditions.